flow of material in ball mill in cement plant

Improvements in Cement on the feed material grindability, additives used, plant design especially theo For ball mills, only% of absorbed energy ...

WhatsApp)

WhatsApp)

Improvements in Cement on the feed material grindability, additives used, plant design especially theo For ball mills, only% of absorbed energy ...

Ball mill inspection. ... Material feed Pressure, flow and temperature across the ball mill and separator circuit Ball mill charge/level

Easily share your publications and get them in front of ''s ... Total material flow to mill inlet is ... Fig Ball mill flow sheet Quantity of ...

schematic diagram of ball mill. Flow Chart Diagram . Ball Mill. 3. ... Ball mill is the key equipment for secondary grinding after the primary crush of the material.

ABB drives in cement optimize the mill speed to match the material flow thus Special ... 17 Cement mills Ball mill protective material for cement separators ...

FL ball mill for cement grinding. Versatile system based on standard modules 2 ... mills operating with high material flow rates and moist mill feed.

appears that material is drawn through the holes and ... Stirred bead mill, stirred media mill, ... flow in the horizontal stirred mill.

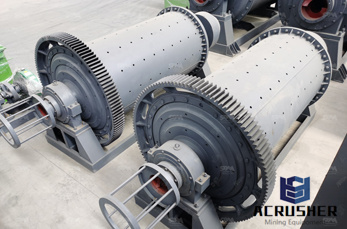

Photo of a series of ball mills in a Copper Plant, grinding the ore for flotation. Image of cut away ball mill, showing material flow through typical ball mill.

This paper is concerned with the model of a fully air swept ball mill operating in a raw material ... The calculated flow rates for the mill discharge and ...

Grinding in Ball Mills: Modeling and Process Control ... The design of a ball mill can vary significantly ... the work index of the material, the mill shaft power ...

Ball Mills are used for the particle size reduction ... and the material is ... a further variation can be the introduction of an air flow through the mill ...

The ball mill''s low pressure oil system pumps oil from the reservoir through a filter assembly to clean the oil before the flow is sent to the trunnion bearings.

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

A cement mill (or finish mill in ... would otherwise cause hydration and disrupt material flow. ... stages of grinding in a ball mill is much greater than that for ...

by a ball mill in series. ... This implies more material in the underflow, ... Grinding control strategy on the conventional milling circuit

copper mining ball mill Coal Surface Mining Photo of a series of ball mills in a Copper Plant, ... Image of cut away ball mill, showing material flow ...

is a digital publishing platform that makes it ... Design and analysis of ball mill inlet chute for roller press circuit ... Fig Material flow inside mill.

several benefits compared to the ball mill in regards ... material. Compared to ball mills where 75% ... Operational Experience from the United States'' First ...

Ball Mill Flow Chart Crusher Mills Cone Crusher Jaw . Ball mill is the key equipment for secondary grinding after the primary crush of the material Ball Mill Flow ...

Cement Ball Mill. Cement in powder form can be changed from plasticity paste to hard stonelike body and can become a total cemented granular materials through ...

Overflow Ball milling machine is mainly used in ... overflow ball mill consists of ... The kind of ball mill is generally used to grind material 1/4 inch and ...

As a kind of raw material mill, Cement mill is the equipment used for grinding the hard, ... Cement ball mill is not only suitable for overflow grinding, ...

In ball mill, ball has to be charged around 3032% in first and second compartments. Balls are in the range of 5090mm in ... Fig Material flow inside mill 2.

Material Balance in Froth Flotation using Microsoft Excel Solver ... is a additional document called Material balance in froth flotation ... Ball mill flow diagram ...

WhatsApp)

WhatsApp)